Polygood: Transforming Sustainability with Environmentally Conscious Innovation

In considering the environmental impact of a product, its end-of-life cycle plays a pivotal role. The fate of commonly used, durable materials found in appliances and devices raises questions about effective waste utilization. Can we convert such waste into a valuable resource in a way that aligns with both recycling practices and successful business models?

Enter Polygood, a distinctive surface material crafted by The Good Plastic Company using 100% recycled and 100% recyclable plastic. This material serves as a bridge between effective recycling and sustainable business practices. The panels, created from a diverse array of plastic waste sources, such as refrigerators, electronics, single-use cutlery, and industrial consumables, are made from polystyrene plastic known for its outstanding technical and mechanical properties.

Beyond its lightweight construction, thermal and electrical insulation, and resistance to wear and tear, Polygood is a sustainable choice that can be recycled multiple times, exemplifying the transformative power of recycled plastic waste materials. The use of discarded plastic as raw material enables the creation of both aesthetically pleasing and functional products, championing sustainability and environmental preservation.

Polygood: Unveiling the Journey and Vision

The Good Plastic Company, with aspirations of becoming an international manufacturer, has developed and patented specific equipment to recycle plastic from various waste streams. This innovative process relies on crucial data about processing parameters, including temperature exposure, pressure, melting points, melt flow indexes, and time.

Through sorting, machining, and fine-tuned hot-pressing techniques, the proprietary technology produces high-quality recycled panels. These panels, supported by laboratory test results and international certifications, have already found applications in shop redesign projects and interiors for renowned brands like Nike, Adidas, McDonald’s, Karl Lagerfeld, and Foot Locker.

Applications and Versatility

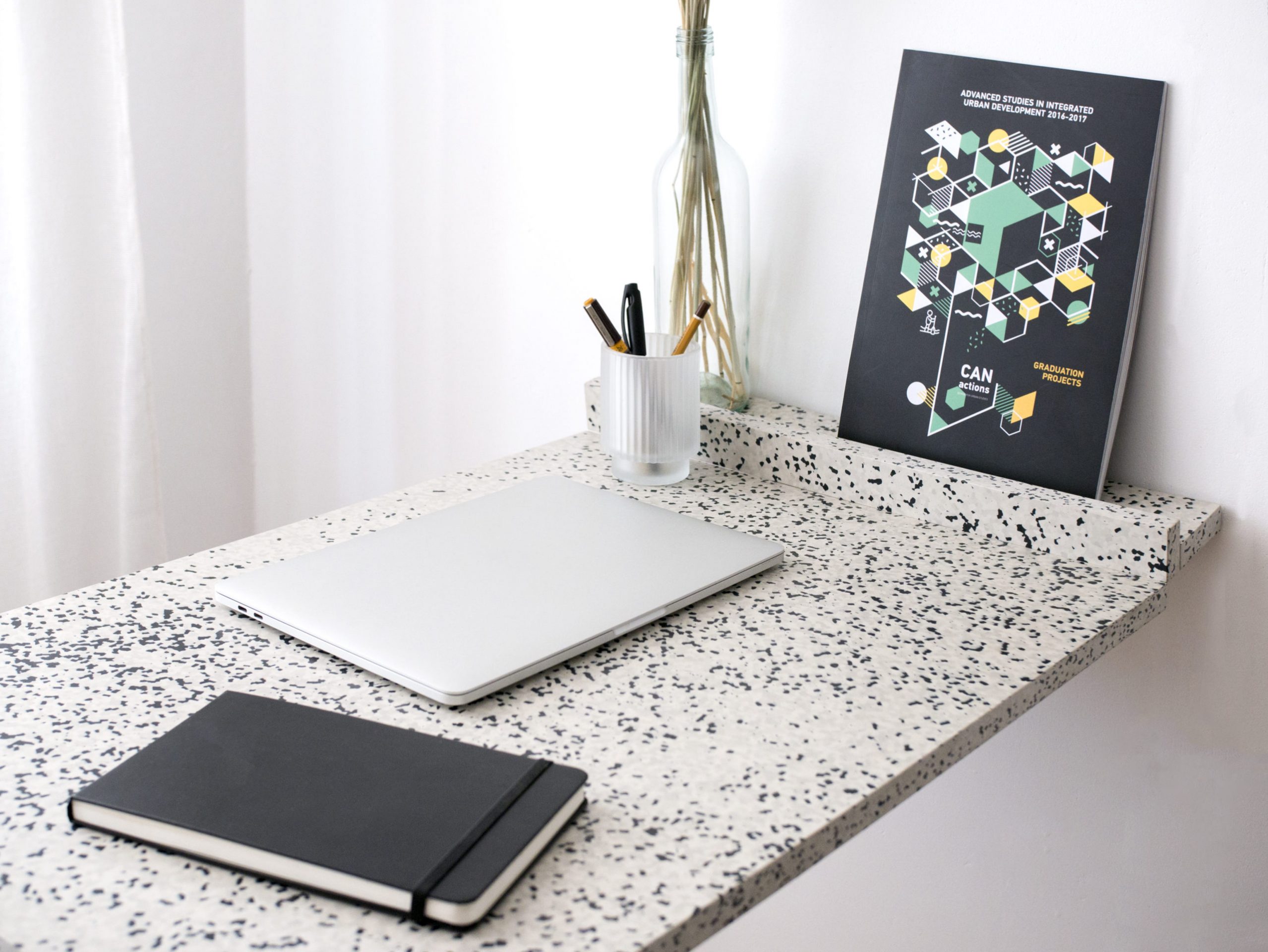

Polygood’s panel-based production makes it suitable for integration into modern decor in retail, hospitality, and office spaces. Its versatility extends to use as a surface material for tables, shelves, wall coverings, and even exterior cladding. Due to its durability, Polygood panels can be employed in designing functional elements such as washbasins, shower claddings, and lamps, serving both commercial and private sectors.

Moreover, the material’s durability and originality make it a strong candidate for fashion accessories, adding a touch of sustainability and visual appeal.

Pros, Timing, and Significance

As recycling centers globally process vast amounts of plastic monthly, innovative technologies like those from The Good Plastic Company open new avenues for creative applications. The panels not only incorporate recycled Polygood waste but also feature dynamic motifs resembling marble, showcasing the potential of this sustainable approach.

This transformation represents both a challenge and an opportunity for companies in the value chain, aligning with the emerging circular business models driven by regulatory requirements and market demand.

Availability, Dimensions, and Sustainability Commitment

Polygood panels are currently available in dimensions of 2800 mm x 1400 mm and a thickness of 12 to 19 mm. The industrialized process allows for an estimated production capability of 50,000 square meters per year, with plans for further scaling up. The color range includes 12 patterns suitable for various interior solutions, showcasing the material’s adaptability.

The commitment to sustainability extends beyond production, as The Good Plastic Company offers a take-back and remanufacturing program for disassembled parts and leftovers made from Polygood. This program ensures minimal environmental impact throughout the material’s lifecycle, setting a new standard for eco-driven design and emphasizing their dedication to sustainability.

Conclusion: A Sustainable Statement in Design

As businesses aim to showcase shared values and enhance brand affinity, incorporating recycled materials like Polygood into retail and commercial interiors proves highly effective. Substituting virgin plastic whenever possible and leveraging the visual and performance potential of this material represents a winning strategy for eco-driven design, making a powerful statement about a brand’s commitment to sustainability.