The Practicality of Polygood: A Human-Centric Overview

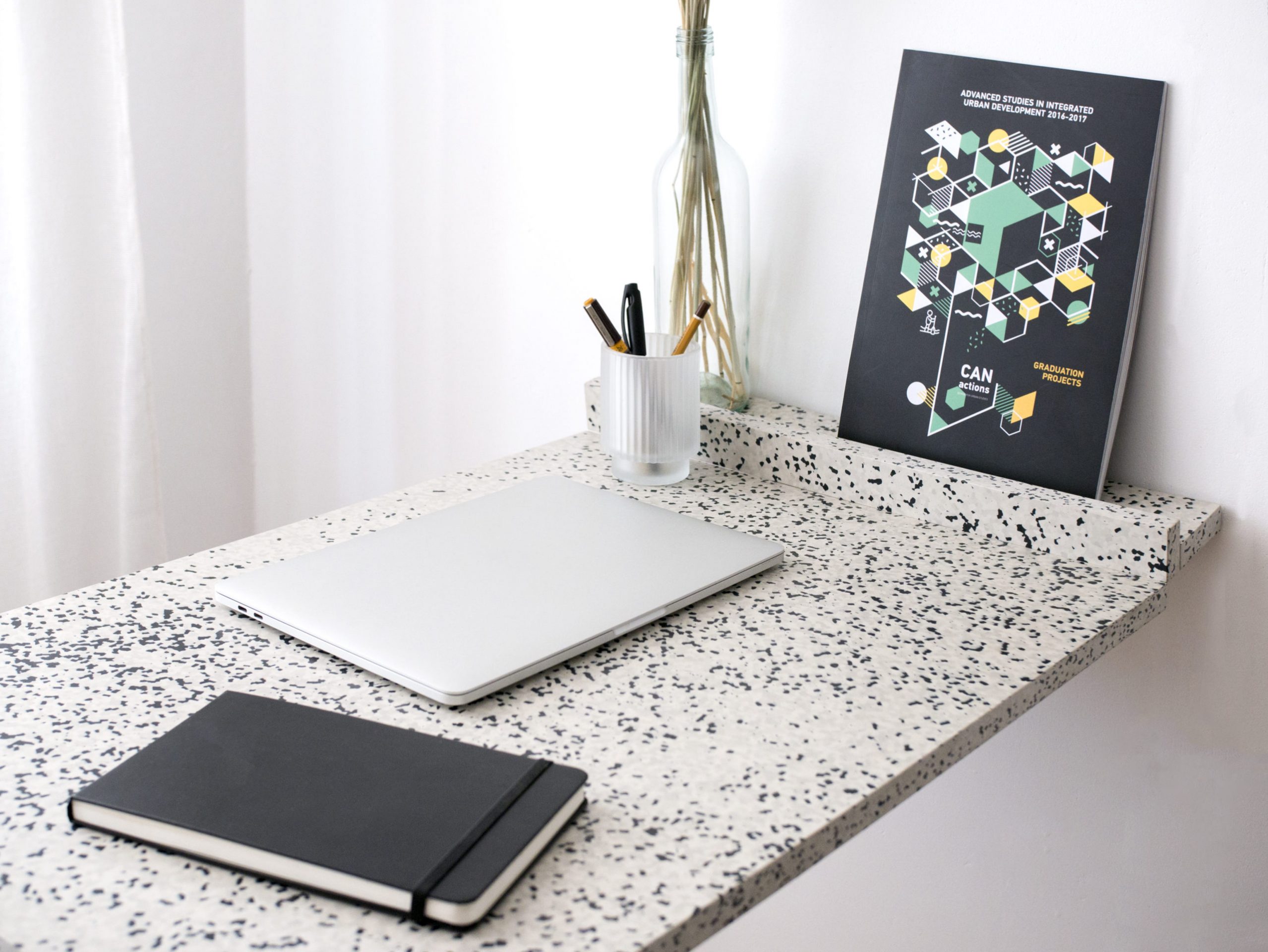

Polygood stands out with its abundant availability and quick turnaround times. Boasting the highest production volumes in the market, we can produce an impressive 100m2 of material daily! Whether it’s wall panels, shelving, retail counters, displays, signage, or storage, Polygood breathes new life into 5-10 tonnes of 100% recycled plastic, making it a versatile choice for department stores, hotel reception areas, and office spaces.

Our panels, the largest on the market at 2800x1400mm, weigh around 100kg, depending on thickness. Operating factories in Ukraine and the Netherlands, we can produce up to 1,000 tonnes of 100% recycled panels annually, meeting industrial-scale demand. Raw materials are sourced from various places, including single-use cutlery, packaging, household electronics, and ocean plastic.

For flexibility, we offer sizes of 1000x1000mm for prototyping and sampling, and 2800x1400mm for actual implementations. Standard thicknesses include 12mm and 19mm, with a ±1mm tolerance depending on the production location. Finish options range from matte (standard) to gloss upon request, ensuring versatility for different needs. Our panels are single-faced and exhibit high stiffness, medium scratch resistance (improvable with coatings), and zero moisture absorption.

The Good Plastic Company’s commitment to using 100% recycled plastics means there may be slight color variations between batches. As waste sources change, so does color pigment consistency. Despite efforts, batch colors may differ due to the inherent nature of recycling. Plastic granules that appear identical to the human eye may exhibit minor color differences when melted into a panel.

For example, black patterns may vary from deep black to matte ashy black, while white patterns can range from a bleached/snow white to a mottled effect comprising off-white and milky white shades. This variation stems from the origin of the material—household refrigerators—and reflects differences in the whiteness of the original appliances before recycling.

To address this, we recommend placing orders for individual projects in one batch and discussing color options and requirements with a sales manager. Additionally, it’s important to note that the surface and interior of our panels may feature small holes and marks, inherent to using recycled source material. While this is beyond our control, our sales managers can guide you on plastic types and patterns that are less susceptible. Surface treatments, such as coatings, can further ensure a more consistent finish, providing a practical solution for your unique project needs.